TECHNOLOGY & QUALITY

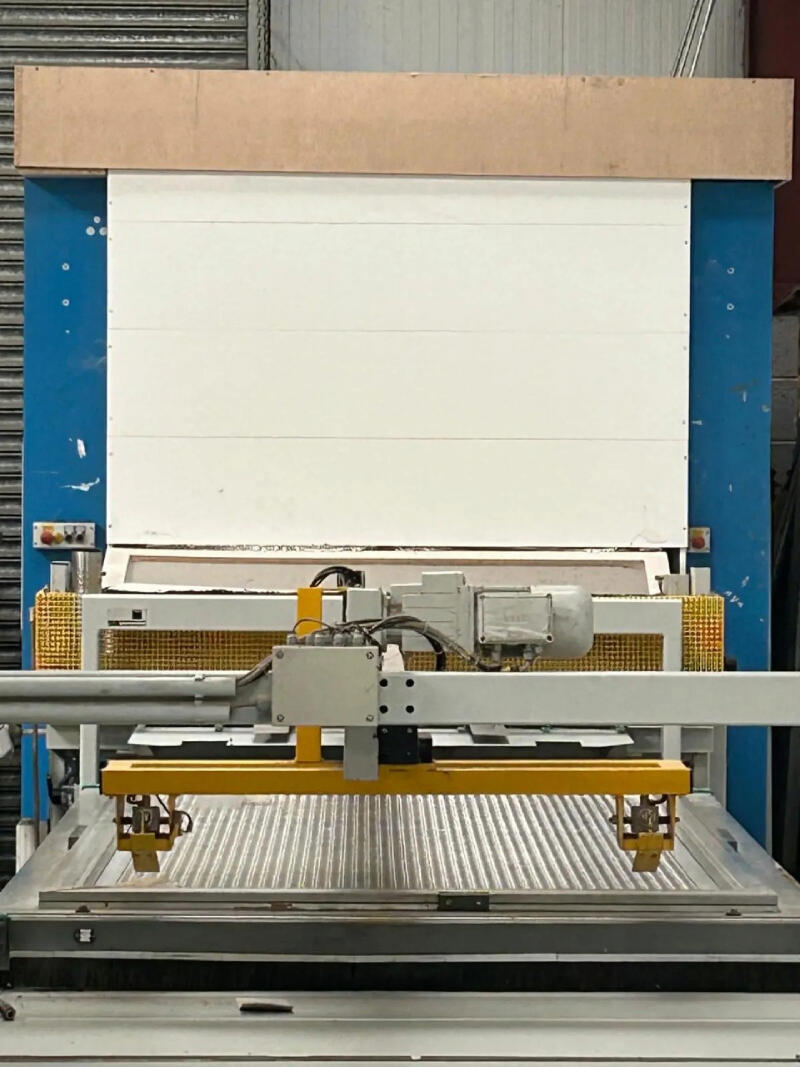

Our company adheres to the principle that modern technology equals impeccable quality. That’s why we constantly invest in new equipment and refine our production processes. At the heart of our manufacturing is an automated lamination line – a high-precision press with characteristics comparable to Wemhöner systems. This press complex performs direct lamination of boards in a short cycle: a board and decorative impregnated paper are placed into the press, where in just a few minutes, under high pressure and at a high temperature, a finished laminated material is formed. The process parameters (pressure, temperature, time) are computer-controlled, ensuring consistent quality from the first to the last board in the batch. Thanks to this, our surfaces have uniform bonding with no bubbles, delamination, or other defects.

In addition to lamination, the company has an entire fleet of modern woodworking equipment at its disposal. This includes CNC panel cutting centers that cut boards with sub-millimeter precision, edge banding machines with automatic feed of edging material and pressure rollers, drilling and insertion machines, and other state-of-the-art equipment. This technical arsenal allows us to take on orders of any complexity and volume while maintaining high precision and processing speed.

We have built a multi-level quality control system covering all stages of production. At the incoming inspection stage, the quality of raw materials is checked: each incoming particleboard or MDF board must meet the specified grade. During lamination, the pressing temperature and pressure are monitored in real-time, ensuring no deviations from the norm. After leaving the press, the boards are cooled under controlled conditions, preventing deformation. Quality Control specialists examine the surface of each laminated board, ensuring it matches exactly with the sample. We test samples for resistance to abrasion, scratching, and moisture exposure in accordance with European standards (DIN EN 14322 and EN 14323).

Certification and Ecology: We are proud that our products meet strict requirements not only for quality but also for safety. All materials we use are certified and approved for residential use. Our particleboards have a low formaldehyde emission level (class E1 or better). The coatings contain no harmful additives. Many products are marked with environmental labels like the “Blue Angel” (Der Blaue Engel). All our products meet the sanitary and hygienic standards of Serbia and the EU.

We implement a policy of sustainable resource use. Offcuts of boards and wood shavings are sent for recycling or safely disposed of, contributing to waste reduction and conservation of natural resources. Our modern presses and machines are energy-efficient, reducing the carbon footprint. The workshops are equipped with an air filtration system capturing wood dust and resin fumes.

Finally, for us, quality means caring about the customer. We strive not just to meet standards but to exceed expectations. Each employee shares this philosophy. Thanks to this approach, our company’s products consistently receive high marks from partners and customers. The combination of advanced technologies, strict control, and passion for our work guarantees you receive the best product on the market.